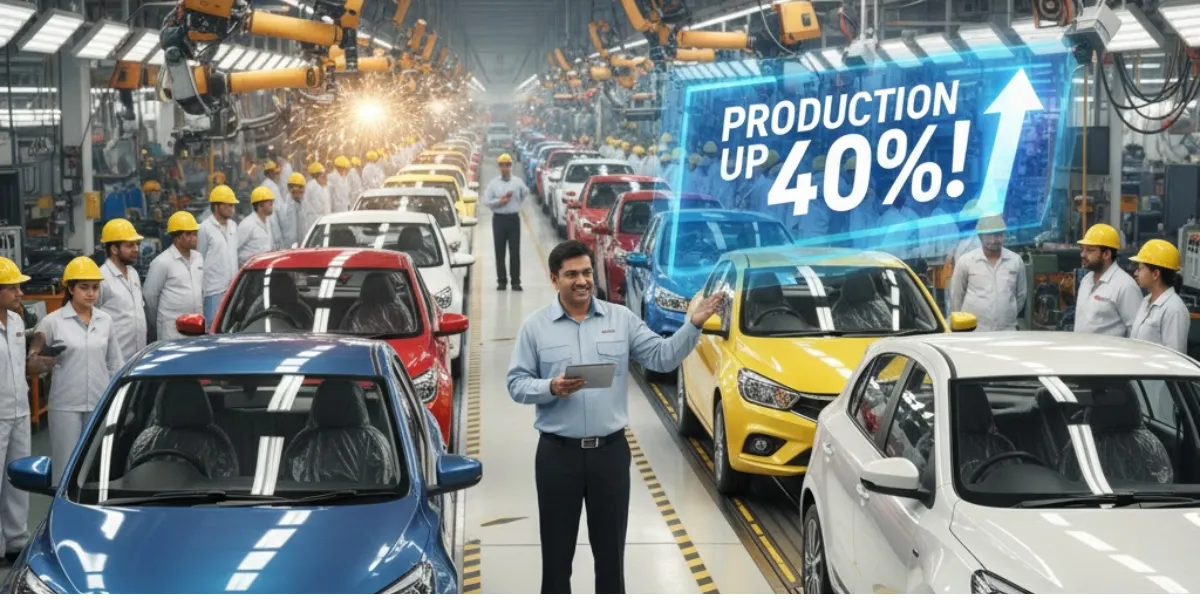

To be straight, the Indian auto industry is buzzing in 2025. Recently, news came out that carmakers in India are planning to increase their production capacity by 30-40%, thanks to recent GST cuts. A friend of mine jokingly said, “Looks like cars won’t just sit in showrooms anymore; they’ll be rolling out fast.” And honestly, it’s not just a showroom story this is a sector-wide shift.

The Real Impact of GST Cuts

As far as I see it, GST cuts do more than just reduce prices. They impact production costs, supply chains, and investment plans too. To put it simply, many manufacturers were hesitant before, but now they’re planning to invest in machinery and add new production lines. I remember back in 2017 during an EV launch, some companies said high GST made mass production tough. Now, those same companies are planning a capacity boost next year.

And here’s another point: small and mid-size makers aren’t sitting back either. They’re confident that demand will grow and lower taxes will keep prices competitive. From my experience, there’s risk at such times, but the opportunity is equally big.

Strategies for Increasing Production

From what I’ve observed personally, ramping up production isn’t just about adding machines. Workforce training, supply chain optimization, and inventory management are being upgraded simultaneously. I recall visiting a Maruti plant last year; even with software glitches, operators were working efficiently. That insider perspective shows that scaling up isn’t just about numbers.

Some companies have even planned flexible manufacturing lines so they can quickly adapt if demand shifts between different models. Simply put, this strategy targets both urban and semi-urban buyers.

Expectations and Challenges

GST cuts will slightly lower car prices for buyers, and manufacturers will get incentives to increase production. But challenges remain raw material cost fluctuations, labor availability, and global supply chain issues. From my experience, software updates can sometimes delay processes, and logistics delays can impact the production line. These are real risk factors that only insiders truly understand.

Here’s another small anecdote one dealer told me showroom traffic has increased, but deliveries are delayed because local suppliers aren’t providing components on time. To be honest, production boost plans are great, but real-world execution is rarely smooth.

What It Means for Cities and the Country

For urban buyers, GST cuts will bring some relief in the prices of small and mid-size cars. And with production ramping up, availability will improve, meaning shorter waiting times. In my view, these moves by policymakers and manufacturers will create excitement in the short term and strengthen India’s auto industry capabilities in the long run.

Bottom Line

I believe Indian carmakers are determined to make the most of this opportunity. Increasing production capacity isn’t easy, but GST cuts have given momentum. Buyers will see short-term price relief, manufacturers get a chance to scale up, and the industry will get a fresh wave of energy. But remember, every strategy comes with its challenges, and insider experience shows that flexibility and careful planning are key for successful execution.